City Gains State-of-the-Art SCADA System

Editor’s note: Remember Y2K and how everyone was worried that the systems would go haywire when presented with a year that ended with “00”? Us too. It’s easy to see it as a joke now but there were some real concerns about it in the late 1990s - understandably! Luckily, everything went OK. We’re all about having your systems prepared for whatever may come, though, which is just what this city did. Read our original case study for an interesting throwback!

Y2K. We’re all aware of it, but do we really know what it could mean to our daily lives? According to Bob Bennett, Chairman of the Senate Select Committee on Y2K, there doesn’t seem to be anyone who can fully answer that question.

“I can’t tell you, are we going to be all right?” said Bennett at a Y2K Task Force Public Forum. “I haven’t got any idea. I can make some guesses and they may be educated guesses, but until the whole system really goes through this there’s no way really to test it in advance. Everything is so interconnected. The power grid is going to work. Of course the power grid is going to work. That’s based on the assumption that the telephones will work. And the telephone system is going to work, and that’s based on the assumption that the power grid is up. And so on, all the way through."

John Hamre, Deputy Secretary of Defense, agrees.

“The Y2K problem is the electronic equivalent of El Niño, and there will be nasty surprises around the globe,” Hamre said.

Amazingly, it seems that industrial automation is more sensitive to incorrect dates than had been originally anticipated.

“At each one of our factories there are catastrophic problems,” said Ralph Szygenda, Chief Information Officer for General Motors, speaking with Fortune Magazine. “When we tested robotic devices for transition into the year 2000, for example, they just froze and stopped operating.”

The American Water Works Association released a survey. It found that many of our nation’s municipal water providers are not prepared for the year 2000. Another survey conducted by a national wastewater association found that only 35 percent of the survey’s respondents expected to complete Year 2000 repairs. During an American-Canadian meeting it was revealed that 10 percent of the large urban water suppliers in the U.S. will not be Y2K compliant when the millennium arrives.

We’ve all read the news concerning the computer glitch that happened during a Y2K test in Los Angeles. At the Hyperion Treatment Plant over 2,000 alarms were triggered in the first hour of the test. It took officials an hour and 15 minutes to realize that nearly 3 million gallons of raw sewage had spilled into a local park.

One northwest city has a different story to tell. Early last year they completed an analysis on the current pump station equipment relative to Y2K, and decided to replace their outdated system with a SCADA system connected to smart PLCs or RTUs.

The city’s senior software engineer in charge of embedded systems conducted a Y2K analysis on the pump station equipment and found problems in the software and hardware as well. He also reported that much of the field equipment was obsolete or unsupported.

Regulatory Requirements

The city also needed to meet new regulatory requirements issued by the Department of Ecology. These regulations required that the current pump station network be able to quantify an overflow at any given permitted site. This was not possible with the older monitoring and data collection equipment in place at the time. When it was installed in the 1980s, data collection was expensive, forcing officials to limit data collection parameters to only minimal data necessary to perform the city’s current business and permit requirements..

Designing the New System

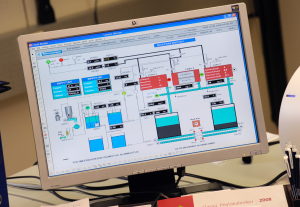

The city decided that in order to meet both the regulatory requirements and avoid any potential for a Y2K incident, a new system was in order. Specifically, one that could provide more data from their field equipment and add intelligence to the remote sites to compute and log lift station flow rates and increase the accuracy of data during overflow events.

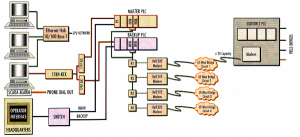

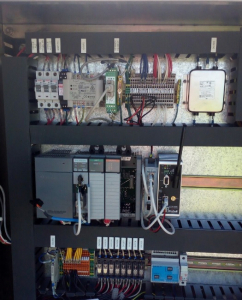

Systems Interface Inc. and Rockwell Automation® teamed up and designed just such a system.

“The customer preferred a nationally recognized, name-brand solution with local distribution and required Modbus® protocol,” said the municipal business manager for Systems Interface. “The solution had to be PLC-compatible and the customer preferred the Allen-Bradley® hardware, yet A-B couldn’t accommodate the need for Modbus.”

ProSoft Steps In

“That’s where ProSoft Technology stepped in,” said Doug Sharratt, President and Lead Developer for ProSoft. “A large number of SCADA projects in the Oil and Gas and Water and Wastewater industries have been specified with the Modbus protocol. ProSoft’s processor, developed jointly by ProSoft Technology and Allen-Bradley, is aimed specifically at these opportunities. It is an Allen-Bradley SLC 5/03 processor that has been modified to include the Modbus Slave protocol.”

Once the Modbus protocol is activated, a Modbus host can read and write data from all the common Modbus data types. In addition, support has been provided for the transfer of Floating Point data. A host can also access the processor Status File S2 to remotely monitor the health of the unit or do such things as setting the real time clock.

“The city couldn’t compute station flow rates, including overflow events, with the past system,” said Systems Interface’s municipal business manager. “Now they can track the well level and integrate it over time to accurately compute and log well inflow, outflow, and how much overflow has occurred.”

More Control, More Information

The new telemetry system consists of a hot backup, redundant, dual processor headquarter master station talking to 72 RTUs at each of the city’s sewer pump stations.

“ProSoft’s Modbus Communication Modules function independent of the PLC, sharing the task of communications and allowing the processor module to concentrate on control and data functions,” said a Systems Interface project manager.

The RTUs monitor the pump station activities and control the operation of the sewage removal equipment, which consists of either pumps or air compressors. The headquarter master polls each RTU via a modem connection, and staff at the headquarters monitor the status and alarms in order to track pertinent data and be able to respond to emergency situations. This is far different from the previous system, which couldn’t track or control any station flow rates.

The new SCADA system, scheduled for completion in late October 1999, will change all of that.

Learn more about ProSoft Technology’s solutions for Rockwell Automation platforms here.