ProSoft 自动控制系统对芬兰废水处理厂的革新

我们习惯只在麻烦发生的时候才去思考它的原因,但是废水处理对我们来说,又是一个很基础的公共服务:它对于保持我们生存环境的卫生和健康,对于保证我们的水源清洁是至关重要的。在这个问题的背后,废水处理过程还是一个融合微生物学,化学以及机械工程学的复杂工艺流程,并且又是包含各类高精尖仪表和自动化技术的现代化产业。

工业废水处理

Lapuan Jätevesi Oy是坐落于芬兰西部的一坐中央废水处理工厂,它负责接收和处理家庭废水和来自于Atria, Lapuan Nahka, Kation 和Metso 电厂排放的工业废水。废水厂运行负责人 Vesa Hahtokari 说,“ 60% 在此处理的水为工业废水,去处理那些包含动物粪便的工业污水,尤其的费力。”Vesa Hahtokari 玩笑道,“相比于工业废水,我不得不说那些生活污水简直干净到了可以直接饮用的地步。”这也侧面说明了谨慎的选择这个污水厂的自动控制系统是多么的重要。

TLapuan Jätevesi Oy 废水厂现在处理来自三个地方的废水,Lapua, Nurmo 以及 Kuortane。此外这套控制系统还负责从 Nurmo 和 Kuortane 到 Lapua 的市政废水管网的监控维护以及地处 Lapua 市的中央废水处理厂间的控制。所以要是对整个的自动化系统进行更新,确实不是一件简单的工作。

精确的控制过程

在废水处理的初期阶段,流入的污水中的大块杂质被去除,并且水中的含氧量被提高足以保证微生物的生长(微生物通过吞食废水中的杂质以净化废水)。在这个处理阶段,废水中的微生物可以得到非常舒适的生长环境,例如温度、氧气和营养。

在下一个阶段里主要二次化学沉积,在这个阶段中,铝基化学药品被加入到第一阶段生化处理后的废水中,用以加速水中有机物质和其他物质的降解。在最后的阶段,残留的污泥被脱水。从污泥中脱离的水被送到整个处理过程的第一阶段重新处理,污泥被送往 Lakeuden Etappi 沼气工厂。

高科技的控制系统

这家中央污水处理厂的控制系统是在1992年安装的,目前这套控制系统已经非常的陈旧,工厂希望更新后的系统应该具有如下特征:

- 易于安装调试和维护保养

- 高度的灵活性以快速适应各种变化

- 对整体解决方案进行改进

- 尽可能的不改变目前应用软件和操作流程

整个新的系统是2008 年施耐德电气和当地的集成商 Seinäjoen Teollisuussähkö Ky合作开发的。“这套旧的控制系统已经尽到了它的职责,过去16年的每一天,我们都在使用它。”Hahtokari 解释到。这套原始的控制系统使用了6套TSX7系列工业控制器, 77/2的监控软件和 MAPWAY 通讯协议。

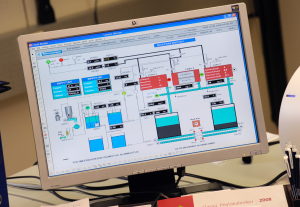

在新的解决方案中,将使用 Modicon 的 Premium 系列控制器作为控制系统,Pro v7.6作为监控软件,并且通过 ProSoft Technology 的9台 RadioLinx 系列工业以太网电台,使用了无线的 Modbus TCP/IP 通讯协议进行通讯。大约2000个过程工艺参数通过无线网络传输,并且该网络也用于远程的程序上下载和远程维护。

为何使用无线?

总共7个控制点必须被整合到一个紧密连接的网络。废水处理厂有两个控制室,6台 Modicon Premium 控制器被安装于不同的房间内。“我们把第二台电脑放在这栋更高的建筑里,确保我们的鞋永远不会被弄湿。” Hahtokari muses 自言自语道。

这是因为工厂被修建在一个容易发生水灾的地方(它的电气中心在去年洪灾后,就不得不重新修整)。当然,即使电脑停止工作,工厂的各项流程也是可以继续运做的。从用户的观点考虑,选择无线网络的第一个优点是它的安装成本和时间:不需要为新的系统通讯再挖电缆沟,也不需要从新清理现有的电缆线路。

正确的选择

从集成商的角度考虑,“ RadioLinx 是安装调试过程中的最简单部分。我们的操作没有任何问题,这些电台非常容易配置而且 ProSoft Technology 产品配套提供的说明资料讲解的非常清楚。施耐德在他们的办公室里做了一些测试工作,并且告诉我们如何实现现场的无线通讯。”

从施耐德电气的观点考虑,无线网络的工程量被减到了最低。“当我们开始项目的时候,我们在现场没有任何无线技术的专家。”施耐德电气芬兰的大客户经理 Jouni Aarnu 解释道。

“我们与 ProSoft Technology 技术支持工程师交谈,并且提供他们基本的工程要求和网络规划。他们针对这个典型的应用进行考虑而且提供给我们推荐的产品清单和每台电台使用的附件装置:转换电缆、天线、避雷器等。

他们同时提供给我们必要的用于产品调试和现场使用的技术说明和建议。在无线电台的安装过程中,只有一个关于天线极性的小问题,但是我们也非常快速的通过与 ProSoft Technology 的技术工程师联系并且解决了它。” Aarnu concludes 说,“在 ProSoft 的专业软件的帮助下,系统的无线网络配置对我们和我们的集成商来说变成了一件很容易的工作。我们从使用 ProSoft Technology 电台的第一个项目中了解到这一点。”

长期的可获利投资

“这些新的控制器大部分被定义成了与以前的控制系统相同的使用方式”。Hahtokari 说道:“有些旧的控制器保持不变,一些被加入一些功能或是更改了一些指令。”自从1992年旧的系统开始运行后,这家污水处理厂又添加了一台新的污泥烘干分离机和并且改进了化学处理工艺。从而,这些自动控制系统也需要相应的更新。

“没有永远保持不变的控制系统。功能总是会有一些增加或是改变。尤其在水处理这个行业,随着时间的推移各种规则和标准总在不断地更新。”施耐德电气的销售经理 Jukka Kiiltomäki 说。Kiiltomäki 正是负责1992年的 Lapuan Jätevesi Oy 的初始自动控制项目,当时也是和 Seinäjoen Teollisuussähkö 进行合作的项目。“关于新控制系统的执行,我们没有任何的问题,用户人机界面上的图表几乎保持于原来完全一致,因此我们熟悉各种操作界面并且不需要提供额外的培训。” Hahtokari 总结道。

目前使用的报文程序不同于 SCADA 系统的程序,但它也是在相同的网络下,直接从Modicon Premium 控制器读取数据。“把报文整合到 SCADA 软件下是可能的,但是由于数据库太大,我们希望把报文保留为独立的程序并且同时保存在一台独立的电脑中。与更新后的自动控制项目连接,我们也同时更新了报文软件。Kiiltomäki 说。

在将来,控制器在需要额外增加输入和输出模块时,可以更加容易地更新控制程序或者对某些功能进行补充。在网络端,因为使用了无线产品的通讯方式,可以为这一切提供了最大的灵活性。

ProSoft Technology 上海(美国普索科技有限公司上海代表处)

上海市徐汇区虹梅路1905号远中科研楼101室

电话: +86.21. 5187.7337

http://cn.prosoft-technology.com/