Guide to Using Industrial Safety Protocols over Wireless Ethernet

Guide to Using Industrial Safety Protocols over Wireless Ethernet

In our latest application guide, we take a look at how you can implement high-performance wireless connectivity for autonomous mobile robots (AMRs). Below, please find details on how functional safety protocols can leverage wireless Ethernet technology to ensure safe, reliable connectivity within your facility; and read the full application guide here.

Beyond improving quality, uptime, and productivity, functional safety is often a requirement in applications leveraging mobile robotics. While local proximity sensors, E-Stops, safety zones, and safety curtains are often used in AMR applications, a SIL 2 or SIL 3 safety rating for the AMR system as a whole requires the use of a SIL 3-rated safety protocol like CIP Safety or PROFIsafe.

Both CIP Safety and PROFIsafe follow the “black channel principle,” which is described in IEC 61508. The black channel principle specifies that two safety devices must have enough intelligence, and enough diagnostics in their communications, to ensure the communication network between the safety devices has zero impact on the ability of the safety device to detect communication errors. In other words, safety protocols like CIP Safety and PROFIsafe have error detection mechanisms built within the safety protocol itself. These error-detection mechanisms consist of time stamps to ensure packets are not lost, delayed, repeated or out of order, and various identifiers and diagnostics to authenticate and validate the messages.

While the safety protocol and safety devices host the intelligence to ensure the safety of the application, there is a risk that a network device, like a wireless Ethernet radio, could have a negative impact on the timing requirements within the error detection mechanism. In a CIP Safety system, the timing expectation is defined by the Requested Packet Interval (RPI), the Timeout Multiplier, and the Delay Multiplier. In a PROFIsafe system, the timing expectation is defined by the F-Monitoring or PROFIsafe Monitoring time. Regardless of which protocol is being deployed, it is important to configure these parameters to meet both your functional safety requirements and your uptime requirements.

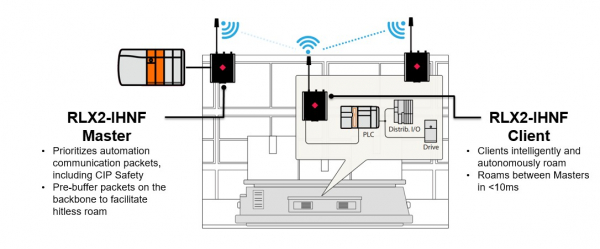

With a focus on both uptime and safety, it’s critical to leverage purpose-built wireless technology to transmit the safety packets as reliably as possible, and with as little latency as possible. The RLX2 product family from ProSoft does just that.

The illustration above shows that there are several RLX2 Masters (Access Points) connected to the traffic processor for the AMR application. As the AMR moves out of proximity of one Master, and into the proximity of the next Master, the RLX2 Client on the AMR needs to roam from one Master to the next. In these applications, the RLX2 Client intelligently and autonomously roams to the next best RLX2 Master in an industry-leading time of less than 10 milliseconds.

In addition to this industry-leading roam time, RLX2 master radios communicate on the backbone to pre-buffer packets in an effort to prevent dropped packets during the roam. This reduces the frequency of wireless retries, resulting in lower latency when compared to competitive wireless systems.

All of this intelligence, engineered into both the Master and the Client, allows RLX2 radios to use the spectrum more efficiency than other competitive wireless systems. As a result, the RLX2 solution only requires one 20 MHz channel for the typical AMR application, which is a significant benefit for the customer.