Remote Connectivity

Considerations for Remotely Connecting to Clients’ Equipment

Post-installation service commitments have provided a new revenue source for machine builders and system integrators, but have also introduced complexities that need to be addressed to ensure remote access is handled securely.

Read moreCollect and Analyze Oil and Gas Applications’ Production Data with Remote Connectivity Solutions

With remote access solutions, your measurement and production data can be automatically sent to your existing SCADA, host, or headquarters location. From there, the data can be analyzed and corrective actions taken if necessary. The detailed data and activity log that’s automatically generated can also help you meet regulatory requirements.

Read moreConnectivity for Water and Wastewater Applications

As water and wastewater service areas and needs expand, robust, wide-ranging connectivity solutions are a must. In addition, equipment that requires monitoring across the application – including pump stations, flow meters, and filtration or sedimentation systems – may use a range of industrial protocols that are incompatible with your control system.

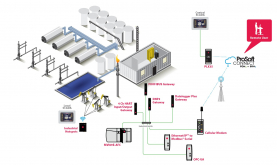

Read moreConnecting Disparate Systems in Oil and Gas Applications

Oil and Gas automation systems are complex and contain technologies from different vendors and platforms. To operate efficiently, it is critical that these disparate systems exchange data. It is also important to get this data to a central location for analysis with the intent to improve productivity and efficiency.

Read moreWireless and Factory Automation Applications

In Part 2 of this series, we examine how wireless solutions keep logistics equipment connected to the rest of the facility in factory automation applications.

Read moreWatch the Tutorial Series: Increase Productivity with Remote Access

Watch our latest tutorial series to discover productivity gains from remote access solutions.

Read more