Communication Solutions for Schneider Electric

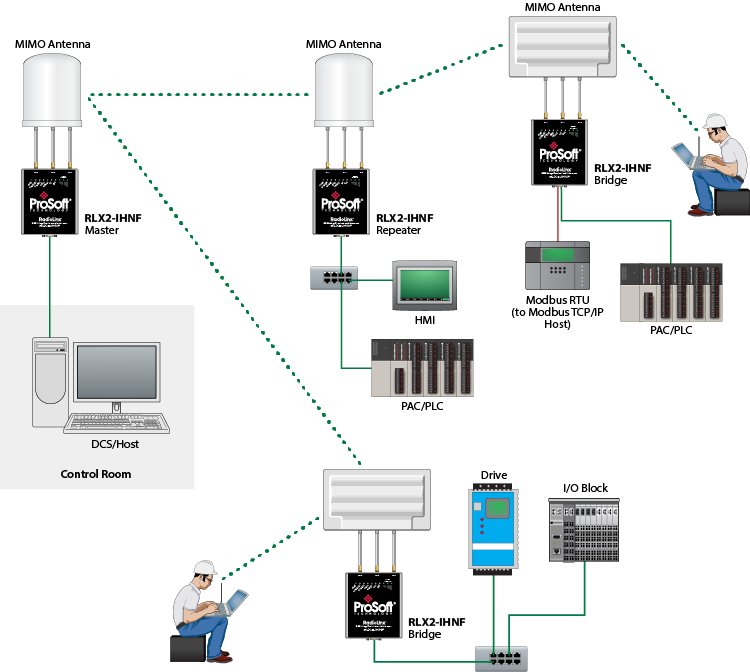

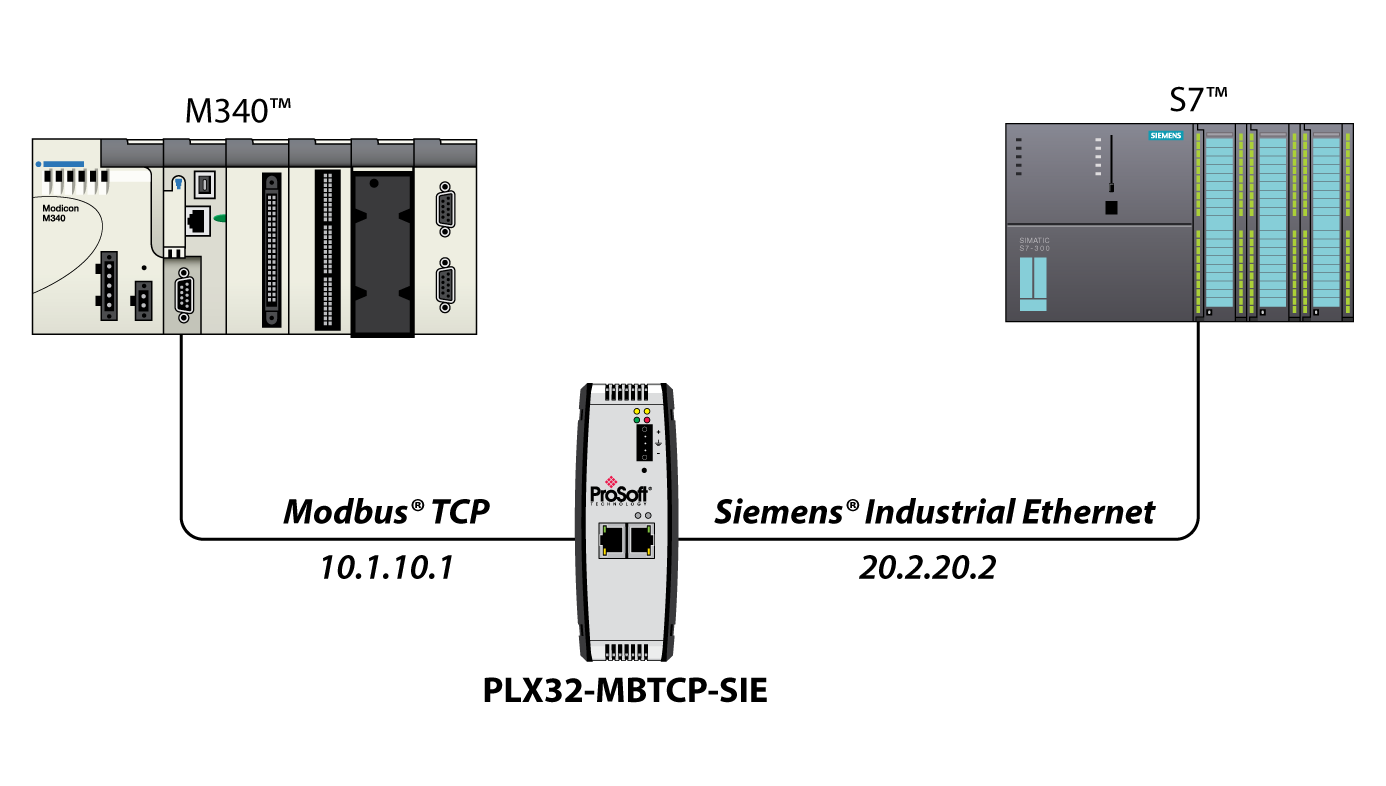

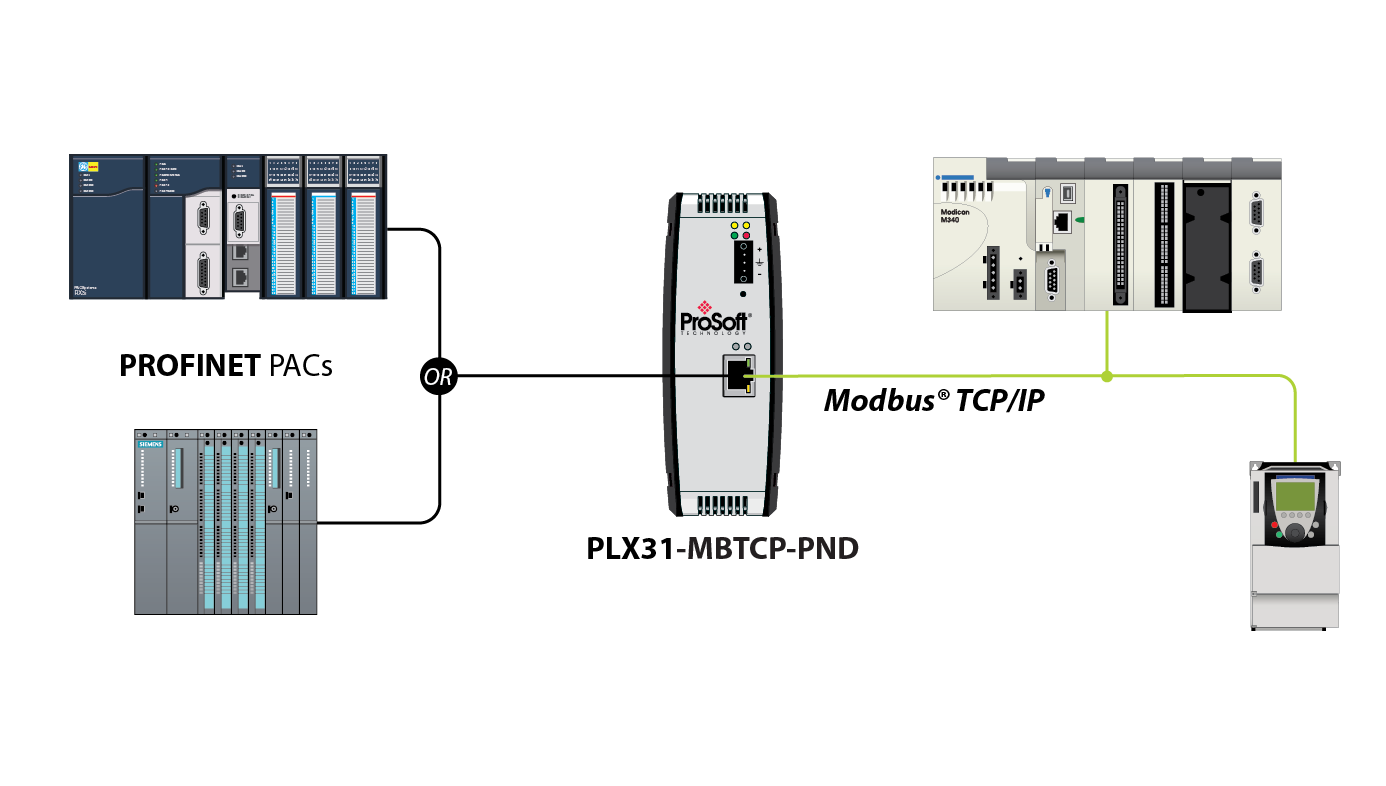

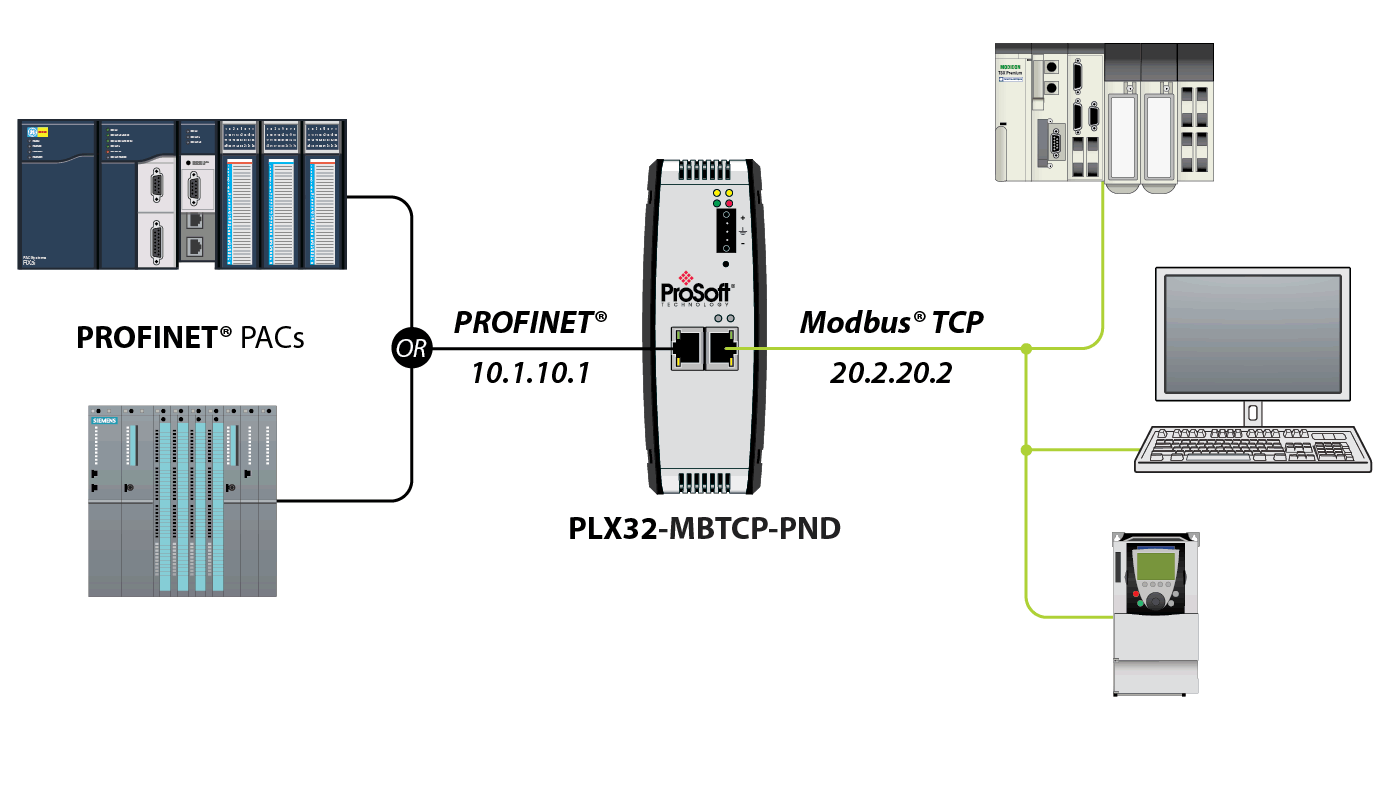

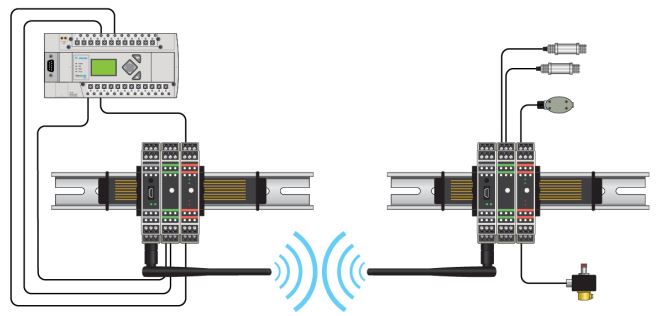

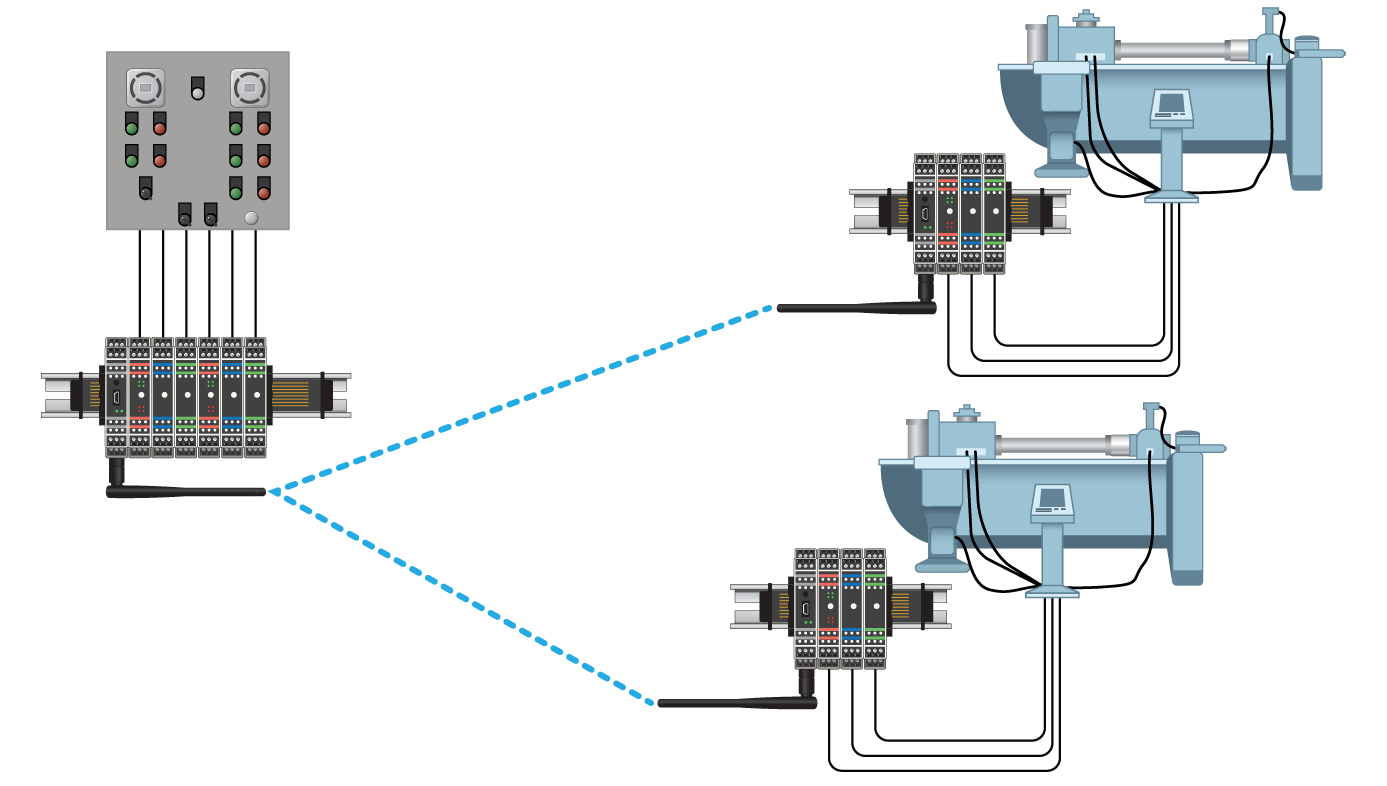

ProSoft Technology provides field-proven connectivity and communication solutions that bridge between various automation products seamlessly

|

|

|

|

|

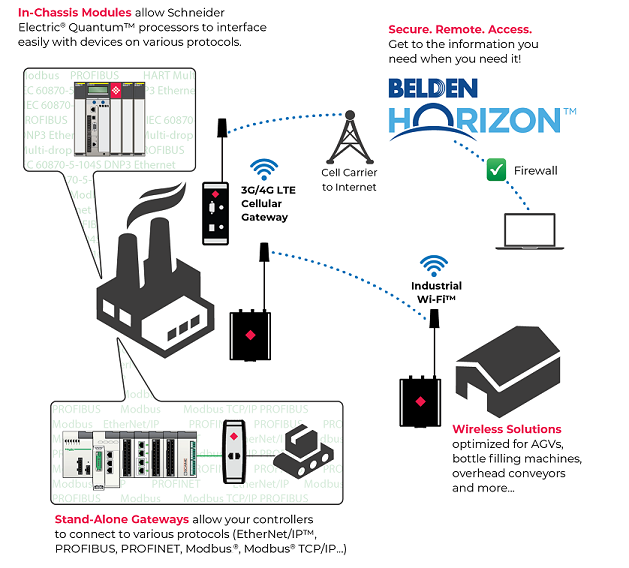

Secure Remote Access SolutionSystem integrators, OEMs, and large end users in particular will appreciate the ease of use that ProSoft Connect offers when it comes to monitoring and programming remote control equipment. With ProSoft Connect, it doesn't matter where you are. All you need is an internet connection! How it helps you...

Save time and money: By being able to monitor and troubleshoot your control equipment in real time from anywhere in the world, you reduce your support travel expenses and you associated time. |

Success Stories

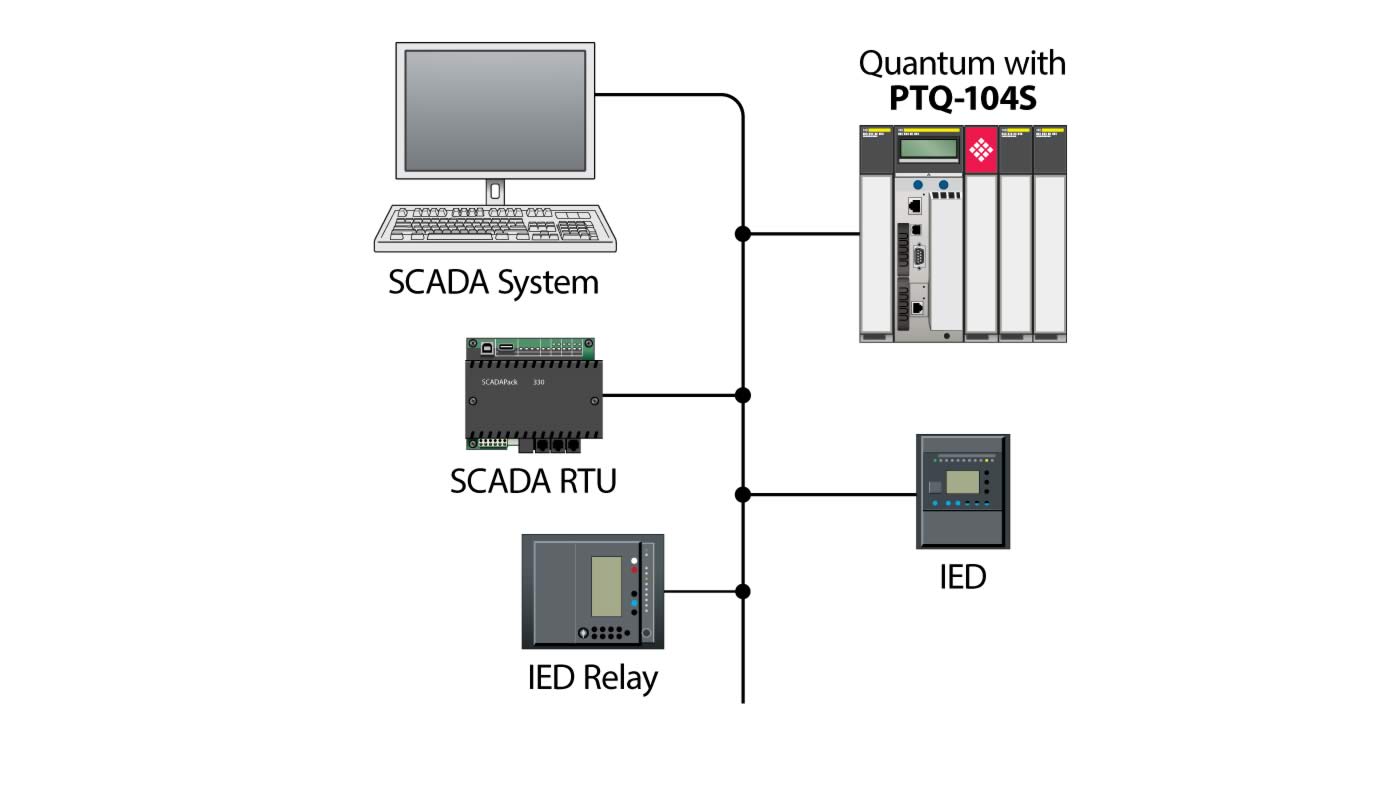

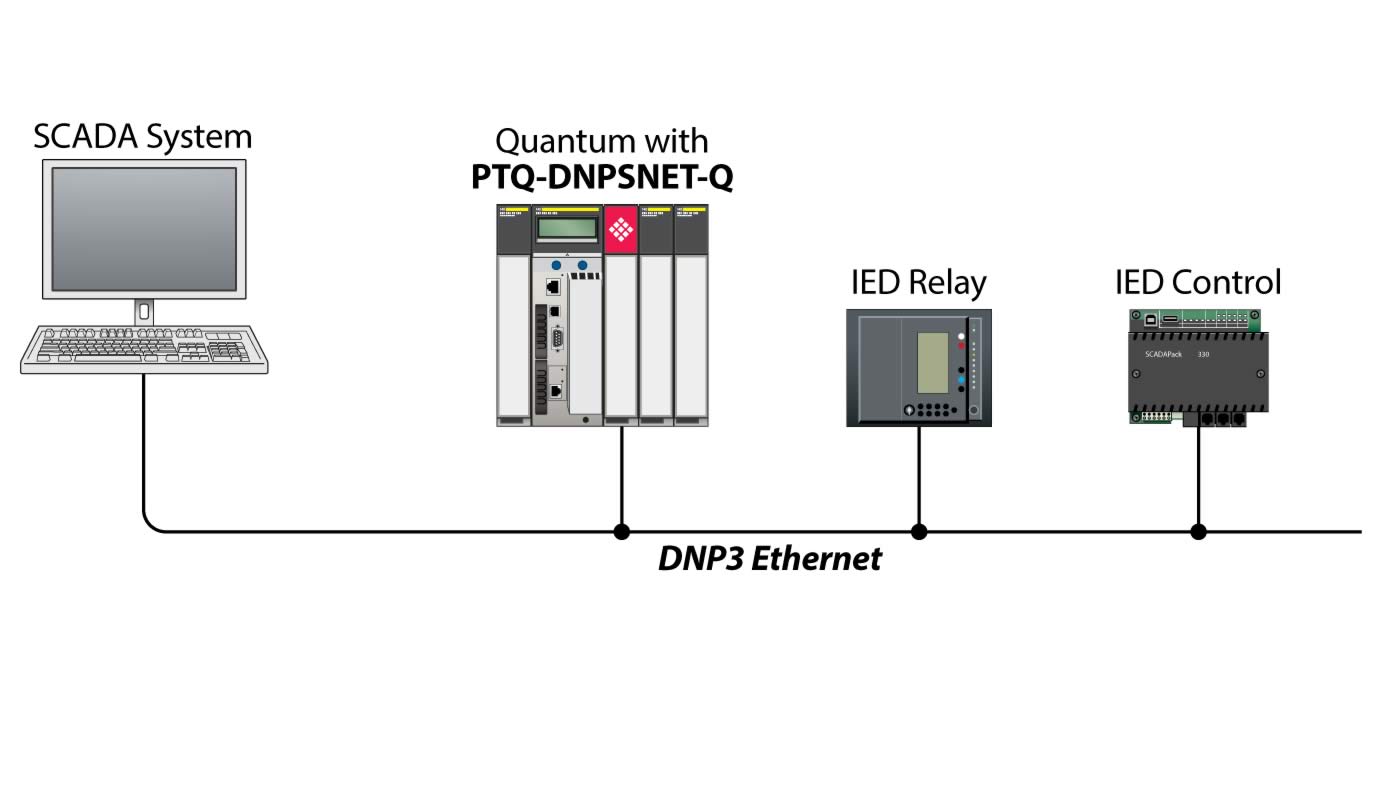

Quantum controller harnesses the power of ProSoft Technology module to connect to DNP3 Network

If you listen you can hear warblers and flycatchers in the undeveloped wilderness of northern Ontario. As your ears become attuned to the solitude of this beautiful area of Canada, you will also hear another sound…rushing water, in the local power generating station.

Read Story

Automation System Renews Wastewater Treatment Plant in Finland

We tend to think about it only when disturbances occur, but wastewater treatment is a basic public service that affects all of us: it is vital to keep our living environment hygienic and healthy and our watercourses clean.

Read Story

Changi Water Reclamation Plant Fit for the Next Century

With a pumping station that is 25 stories tall, the Changi Water Reclamation Plant, located on the diamond-shaped island of Singapore, is the cornerstone of the Singapore Deep Water Sewage System.

Read StoryTrending articles by Schneider Electric

The next wave of IIoT-related business improvements

It’s become quite clear that the Industrial Internet of Things (IIoT) is the future of Industry. By now we’ve well and truly covered the point that IIoT is, in fact, not hype. For end users and OEMs IIoT, cloud and big data analytics are creating very real business opportunities [...]

Read moreIIoT Deployment and Legacy Equipment

The first key concept in IIoT deployment involves securing systems. Product lifecycle has a huge impact on security in industrial applications. Unlike IT environments, products can remain in active service in industrial control systems for as long as 30 years [...]

Read moreSecurity: The Key to Successful IIoT Deployments

The Industrial Internet of Things (IIoT) has been a hot topic of late. One key consideration that will impact its acceptance rate and ultimate success is security [...]

Read more