Mining and Metals

Solutions

Whether you need clear communications in a harsh environment, modules to connect a variety of protocols, or a way to remotely access tough-to-reach equipment, ProSoft’s solutions are up to the challenge.

Connect your mining and metals

Our communication solutions have been designed for the harsh environments in mining and metals. Functions such as stacker/reclaimers, open pit and underground extraction, and conveyance of materials use drives, motor control centers, and SCADA systems that may not communicate with your new control system. We have communication solutions for:

- Modbus®

- Modbus® TCP/IP

- PROFINET

- EtherNet/IP™

- PROFIBUS DP

- HART

- Many more

With these solutions, you will not only control these systems – you will also be able to gather additional data that can be analyzed and acted upon to reduce energy usage/costs and downtime.

Wireless and Remote Connectivity Solutions

Wireless Communications

In a wide-ranging mining or metals operation, a strong wireless communications network is essential.

Our Industrial Hotspot radios feature an EtherNet/IP embedded object and Modbus agent support, allowing you to get wireless diagnostic information into your PAC/PLC. Your operations can now identify potential network problems to your IT network personnel, helping to reduce unscheduled downtime. The radios also feature Ultra-Fast access point switchover times, which is ideal for applications where your control devices move and need access to multiple radios.

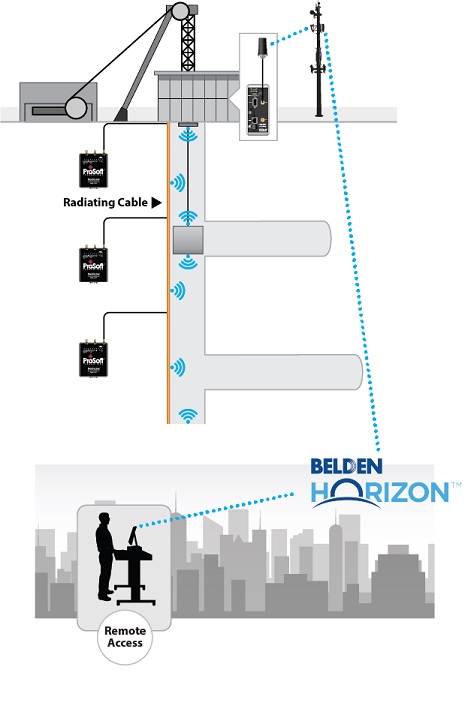

Radiating cable can be used in underground mining applications and other projects where a flexible solution is a must, or used in conjunction with MIMO antennas and wireless radios in mine winder applications.

Remote Connectivity

One of the keys to minimizing unscheduled downtime is getting the right person the information they need wherever they are. Using ProSoft’s cellular gateway in conjunction with Belden Horizon™ platform (formerly known as ProSoft Connect®), your support personnel can securely access your automation equipment remotely. Scalable subscription-based Belden Horizon plans are also available for those who need to manage multiple projects, such as system integrators or OEMs.

Substation and Intelligent Motor Control Applications

Substation Automation Solutions

Power distribution plays a big part in every mine, and being able to monitor your substation devices is critical. These devices often communicate via:

- DNP3

- IEC 61850

- Modbus

- Modbus TCP/IP

- IEC 60870-5-101

- IEC 60870-5-104

Our solutions communicate with DCS systems, Rockwell Automation®, Schneider Electric®, Siemens®, or GE controllers or SCADA systems to ensure that you’ll have the information that you need when you need it.

These communication solutions can help you:

- Monitor the status of your intelligent electronic devices

- Determine protections status to ensure that your operation is running safely

- Monitor and control circuit breakers

Intelligent Motor Control Centers

IMCCs contain power monitors, circuit breakers, intelligent motor starters, drives, and soft starters that are connected to a network and need to be connected to your controller and/or SCADA system. We offer solutions for:

- EtherNet/IP

- Modbus TCP/IP

- PROFIBUS DP

- Modbus Serial

Having the data supplied by these devices where you need it will help you diagnose and troubleshoot problems, or analyze operational performance quickly. This can minimize your unscheduled downtime and improve your bottom line.

Accessing Your Data

Accessing your mining and metals data can help you optimize your resources, gain historical perspective on equipment diagnostics, and make informed business decisions.

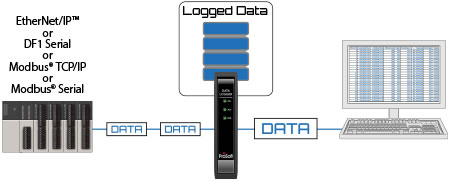

Data Logger

ProSoft’s Data Logger allows you to see your equipment’s diagnostics and performance history before you go on site so you can have an advanced view of any issues. This solution is especially ideal for hard-to-reach operations, and does not require an existing network infrastructure.

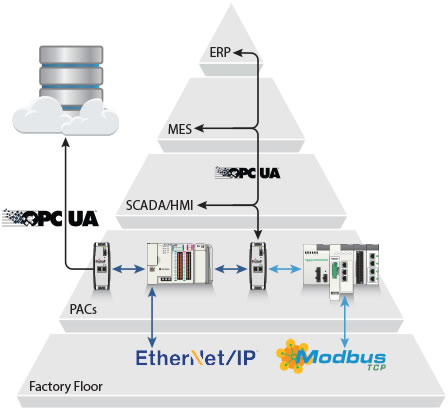

EtherNet/IP-Modbus TCP-OPC UA Gateway

Your EtherNet/IP and Modbus TCP equipment likely holds some valuable data – but how can you get to it? This module connects those protocols simultaneously with a built-in OPC UA server, which will send your equipment’s data to your MES or ERP. From there, you can easily access your data, analyze it, and make business improvements based on the information.

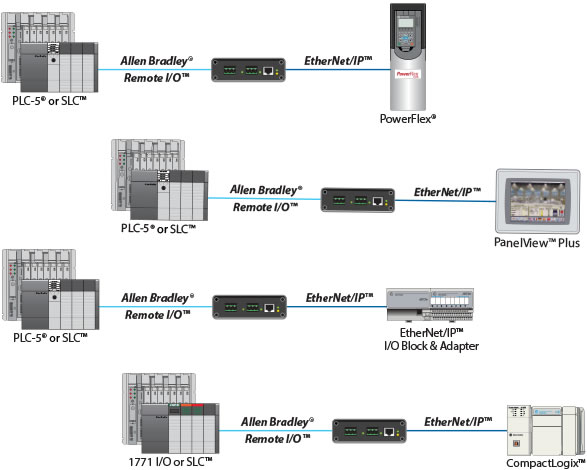

Phased Modernizations and Migrations

Maintaining and upgrading old control equipment when you ran out of spares used to necessitate significant downtime and required an entire system to be upgraded. The new system would need to be wired and programmed; personnel trained; and new spares brought into stock. But what if the upgrade went on longer than planned?

We have good news: ProSoft Technology can help with our Phased Modernization and Migration solutions. Our modules allow you to modernize your control system in phases, according to your timetable, and help you minimize scheduled downtime, spread out the costs involved, and minimize risk.

Real-World Examples

From Walkie-Talkies to a Robust Wireless Setup

The Durgapur Steel Plant in India installed wireless solutions after years of using walkie-talkies to communicate plant issues. Now, they report, “this communications network has allowed us to minimize frequent downtime.”

MORE INFO

Radios up to metallurgy plant’s communication challenges

A metallurgical plant in Ukraine needed communication solutions that could stand up to its harsh environment – its previous setup had limited range and data loss. Its new wireless radios help ensure clear communications between the control room and the plant’s scale cars – and the Wi-Fi connection stays strong, no matter what’s happening in the plant.

MORE INFO

Castings plant sees better ROI with a phased modernization

American Castings instituted a phased modernization of its plant’s legacy system. They’ve estimated a cost savings of over $100,000 in lost production and implementation time, and about 140 hours’ worth of work.

MORE INFO