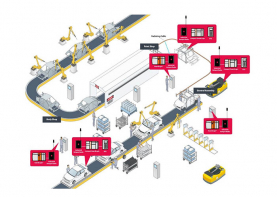

Automated Material Handling

Your Comprehensive Guide to Wireless Functional Safety Applications

With each new advance in technology, wireless communications achieve better performance. There are some cultural and technical barriers that must be addressed at companies adopting wireless communications within operational environments, such as achieving employee safety.

Read moreCritical Considerations for High-Performance Wireless Automation Systems

Wireless technologies make advanced mobile automation systems more valuable in every way. This blog post lays out the best practices and preparations you should make when considering wireless technologies for your mobile automation application, and breaks it down into three key takeaways.

Read moreStellantis increases production flexibility with new conveyance system

Key to any company’s success is innovation and keeping up with the times. A major vertical that deals with this constantly is the automotive industry [...]

Read moreAutomated mooring system finds consistent connection

An OEM in Italy has found an alternative to for busy ports: Its automated vacuum solutions moor and release ships quickly [...]

Read moreSystem integrator solves protocol clash in Italy

A system integrator in Italy tends to use Siemens® with PROFIBUS already integrated. A recent customer requested a Rockwell Automation® CompactLogix™ for its filling machine [...]

Read moreWireless radios perfectly suited to automotive companies’ moving equipment

Smart conveyors are time-saving equipment that have helped factories around the world cut costs and increase efficiency. Tapping into those results, though, requires an investment [...]

Read more